Crisis management in operations - the daily control room in production

In this blog we now want to talk about the Production Control Room (or "War Room"), which is a central element in crisis management. Basically, it is a place where all relevant crisis management information comes together and where you can exchange information about the current crisis status on a daily basis.

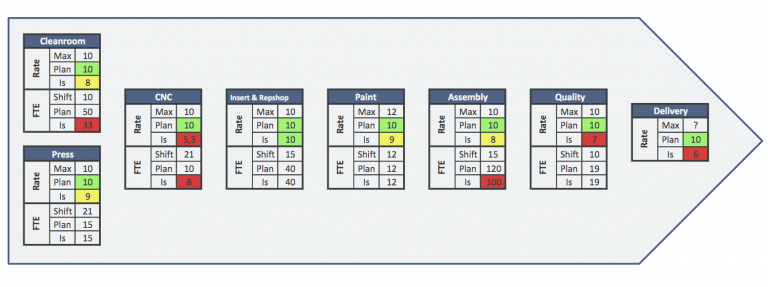

The structure of the Control Room follows the value creation process (see below for an example of a typical composite manufacturer):

All relevant process information is updated daily and posted on the control room wall. Depending on the crisis mode, all stakeholders meet once or twice a day to go through the relevant KPIs, address important issues and take appropriate action if needed (and there always is in a crisis).

The head of the control room is the crisis manager (a kind of programme management profile). In our projects, it is often the case that foliofive takes on this role and hands it over to a member of the client's staff after a given time. We usually start with an overview of the current delivery status compared to the plan. Then the responsible managers report on their most important input elements. These are usually the material input (purchased parts and raw materials), the engineering input (drawings, late changes, ...) and tool changes and the status on new tools to be ordered or adapted.

The KPI for material is presented by a representative of procurement and contains for all critical items a status about the current stock (called range and measured in weeks) and information about the replenishment time (also measured in weeks). Key questions: Are all materials available or is there a risk of a bottleneck because the stock is less than the replenishment time? The Control Room enables an immediate comparison of the information. Does production confirm that all materials are available? This is one of our standard questions.

Design provides an overview of the latest changes, i.e. the availability of their input from the customer, the status of the designs and the possible impact on new tools to be manufactured or changes for procurement from the supplier. The status of the tools (designed, delivered, ready for use, first article inspection performed) follows directly after the engineering report. From our experience, the interface between engineering and procurement often does not work well enough. As a result, valuable time is often lost in steering changes through the supply chain.

In the next step, production reports the current status per workstation. The minimum information is the daily output achieved compared to the plan, the recovery measures if the plan is not achieved and an outlook as to whether the weekly target can (still) be achieved. On Wednesday at the latest, information must be provided on whether additional shifts are needed on the weekend for recovery and how this has been organised. In addition to the Control Room, a weekly Planning Review Meeting is mandatory, in which planning, production, logistics and control meet regularly. The purpose is to review the previous week's performance across functions. If there was a shortfall, the unmet workload must be added to the next week's target (rolling forecast) to meet the overall target.

After production, quality is asked to provide the current status of the key KPIs. Normally they should be organised as gates along the production process. In the Control Room, the main focus is on their development over time. Detailed investigation (including Pareto analysis, DMAIC, etc.), reporting and control is done in a separate weekly Q-board, which is as mandatory as the Control Room.

Any new actions or decisions during the Control Room meeting are entered into our crisis action tracker. Usually the deadlines for actions are very short and a dedicated person should be appointed to control the timely completion of the actions.

At the end, we finish the Control Room with a look at the current product delivery schedule. Are we on track in terms of our given commitment? Is there anything else we can do to keep the schedule? If the answer is a clear yes, we go back to the workshop and continue our work.